JDW Case Study - Jackson Electrical Industries

From its humble beginnings in an Epsom garage in 1977 to a multi-million-dollar export business, Jackson Electrical Industries has had JDW Chartered Accountants Limited alongside it all the way. This is a story of innovation, friendship and longevity.

Early Beginnings

Jim Jackson won a design competition while studying to become an electrician, and that sparked his keen interest in product design. The garage was replaced for a larger version in 1978, but the business outgrew it rapidly, so they moved to premises in Onehunga.

The Lifeguard Power Distribution System for construction sites was successful, as it was easily installed, provided a much higher level of safety for staff using power tools and is fully reuseable on the next construction site. The product is still in production today, though it has been redesigned and adapted for different environments over the years.

With help from his parents, Jim and Carolyne bought a rundown house in Onehunga and built their first factory. They have gradually acquired adjoining buildings and occupy around 8000m2 of building and employ 80 staff members.

Innovation by Design

Jim loves to find novel solutions to problems and has a knack of turning them into profitable products and services, such as the Rugged Light for construction sites, which can even work under water. Jackson Electrical Industries holds several patents. Safety is their first priority, so their products are often designed to higher standards than required by regulators. They were involved in introducing an IEC Standard for the Rugged Light.

Jackson operates some of the largest 5 Axis CNC (computer numerical control) machines in New Zealand. The CNC operation provides machined parts for not only Jackson Industries company products but they also undertake work for other companies involved in the manufacture of hydrofoils, aerospace componentry, marine propulsion, as well as complex moulds for decorative concrete panels used on large buildings, tunnels and motorways.

Their products require a very high degree of precision, so their concrete factory floor is 1.5 metres deep under their most recent CNC machine!

In 2010 they developed a complex polyester material called “CaroC” which enables them to produce complex moulds faster and cost competitively. To meet increasing demand, they installed semi-automated mixing and delivery operation for this complex resin, where they can batch mix up to 2 tons of material in single job lots. In 2015 Jackson Electrical Industries won the QBE Exporter of the Year Award.

JDW’s Services Grew alongside the Jackson Business

As time has gone on, Jim and his company’s requirements for accounting, tax and trustee services have increased. Our Tracy reviews the monthly management reports, comments on trends, discusses issues which arise and makes recommendations for provisional tax payments. We recently lent a member of our JDW team to Jackson’s in-house finance team, to cover an illness.

JDW has advised the family on appropriate ownership structures for their industrial and commercial properties and Murray continues to advise the family on trust matters. Tracy took care of tax matters for two societies which Jim chairs, Manukau Harbour Restoration Society, The Onehunga Enhancement Society and the Clarks Beach Public Wharf Society.

A Tale of Lasting Friendship

In 1977, Jim was looking for a local and trustworthy accountant and connected with Murray Wells. It was not long before Jim and Murray became close friends, and they have since co-owned yachts and holidayed together.

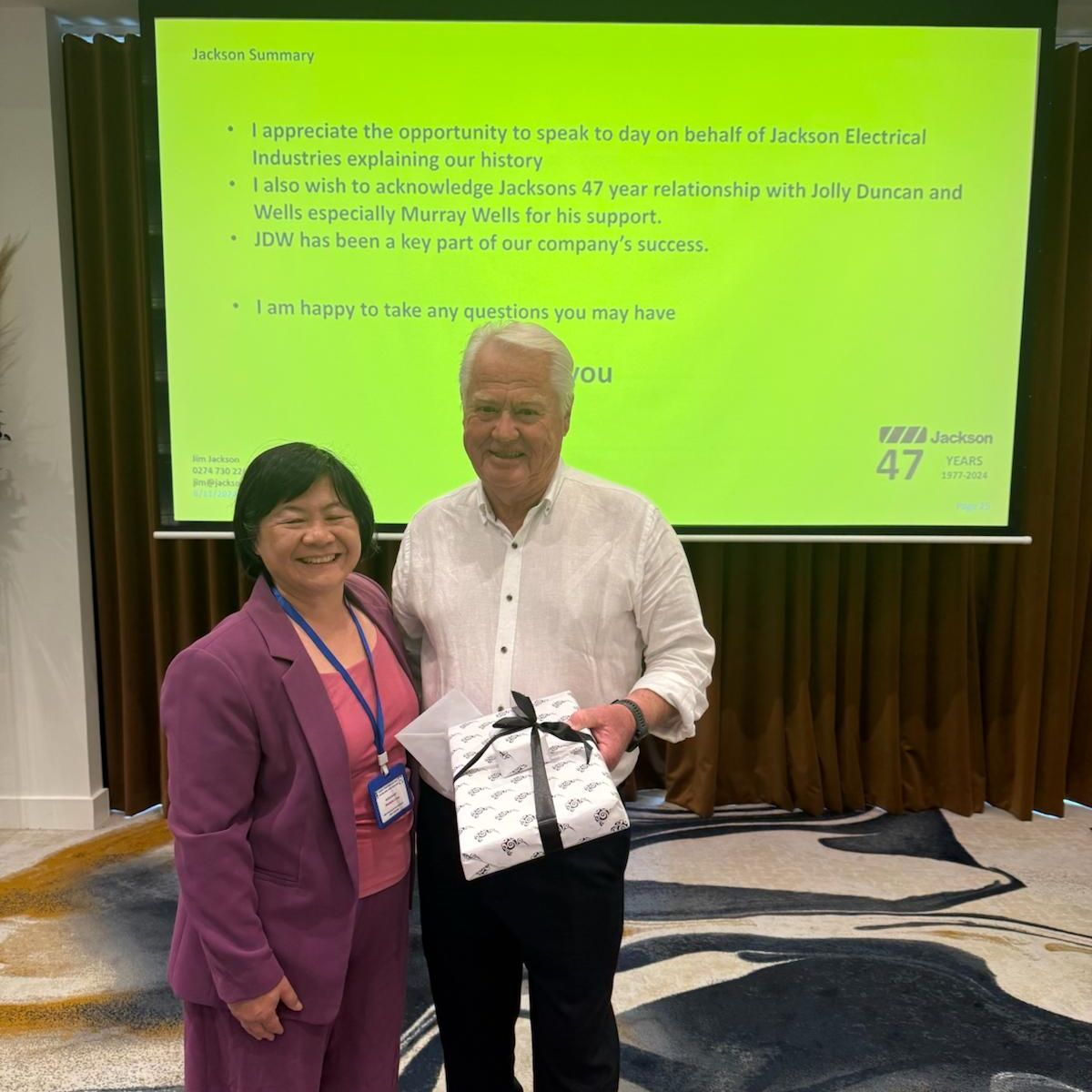

As Jim is passing on the Jackson torch to sons Mark and David, and Murray is passing on his JDW torch to Tracy Bian, the close connection between Jackson Electrical Industries Limited and JDW Chartered Accountants Limited remains strong, and we hope will last for many generations.

- Serena Irving

Serena Irving is a director in JDW Chartered Accountants Limited, Ellerslie, Auckland. JDW is a professional team of qualified accountants, business consultants, tax advisors, trust and business valuation specialists. We are incredibly grateful to Jim Jackson and Jackson Electrical Industries for allowing us to present this case study and their photos.

Download a PDF version here or contact the author by email. Like our Facebook page for regular tips.

An article like this, which is general in nature, is no substitute for specific accounting and tax advice. If you want more information about the issues in this article, please contact your adviser or the author.